Expert technical support for electrical industry challenges.

Expert technical support for electrical industry challenges.

Blog Article

Top Tips for Effective Electrical System Troubleshooting

Repairing electrical systems requires a systematic approach, based in an extensive understanding of electrical concepts and safety methods. By familiarizing oneself with circuit parts, using important devices, and adhering to an organized assessment approach, professionals can properly identify and settle issues. Nonetheless, the nuances of reliable troubleshooting expand past simple technological understanding; recognizing just how to record findings and prioritize safety and security can significantly affect end results. As we explore these important components further, it ends up being clear that understanding this process is not just beneficial yet essential for success in the field.

Understand the Fundamentals

Recognizing the basics of electrical systems is necessary for efficient troubleshooting, as a strong foundation allows specialists to diagnose and deal with issues more efficiently. A thorough understanding of electric principles, such as voltage, current, resistance, and power, is critical in recognizing the origin triggers of issues. Voltage is the electrical possible distinction that drives present through a circuit, while resistance opposes the circulation of present, affecting the general functionality of the system.

Familiarity with circuit parts, including resistors, capacitors, diodes, and switches over, is additionally critical. Each component plays a distinctive function in circuit behavior and can influence efficiency when malfunctioning. Additionally, understanding collection and identical circuit setups is important, as these arrangements influence the circulation of voltage and present within the system.

Service technicians have to be aware of potential risks, such as shock and brief circuits, to apply safe troubleshooting practices. By grasping these foundational ideas, professionals enhance their capability to perform effective diagnostics and repair work, eventually leading to enhanced performance and dependability of electric systems (electrical system troubleshooting).

Gather Necessary Equipment

Efficient troubleshooting of electrical systems calls for the ideal set of devices to identify and fix issues properly. Necessary tools consist of a multimeter, which determines voltage, current, and resistance, permitting for exact assessments of electric elements.

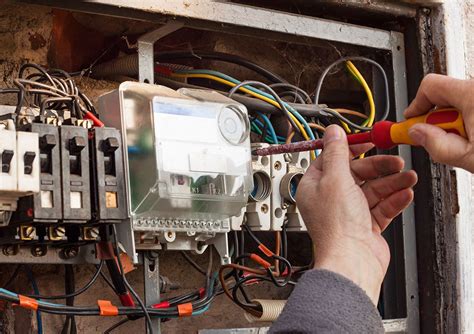

Additionally, protected hand tools such as screwdrivers, pliers, and cord strippers are crucial for securely manipulating electric connections. It is additionally a good idea to have a circuit tester on hand to validate the presence of voltage in electrical outlets and cables. For even more complicated systems, a thermal imaging camera can help discover overheating parts, suggesting possible failures.

Comply With a Methodical Technique

Having actually collected the ideal devices, the following action in repairing electric systems is to comply with an organized approach. A systematic technique ensures that technicians can identify mistakes successfully and properly, minimizing downtime and stopping unnecessary repairs.

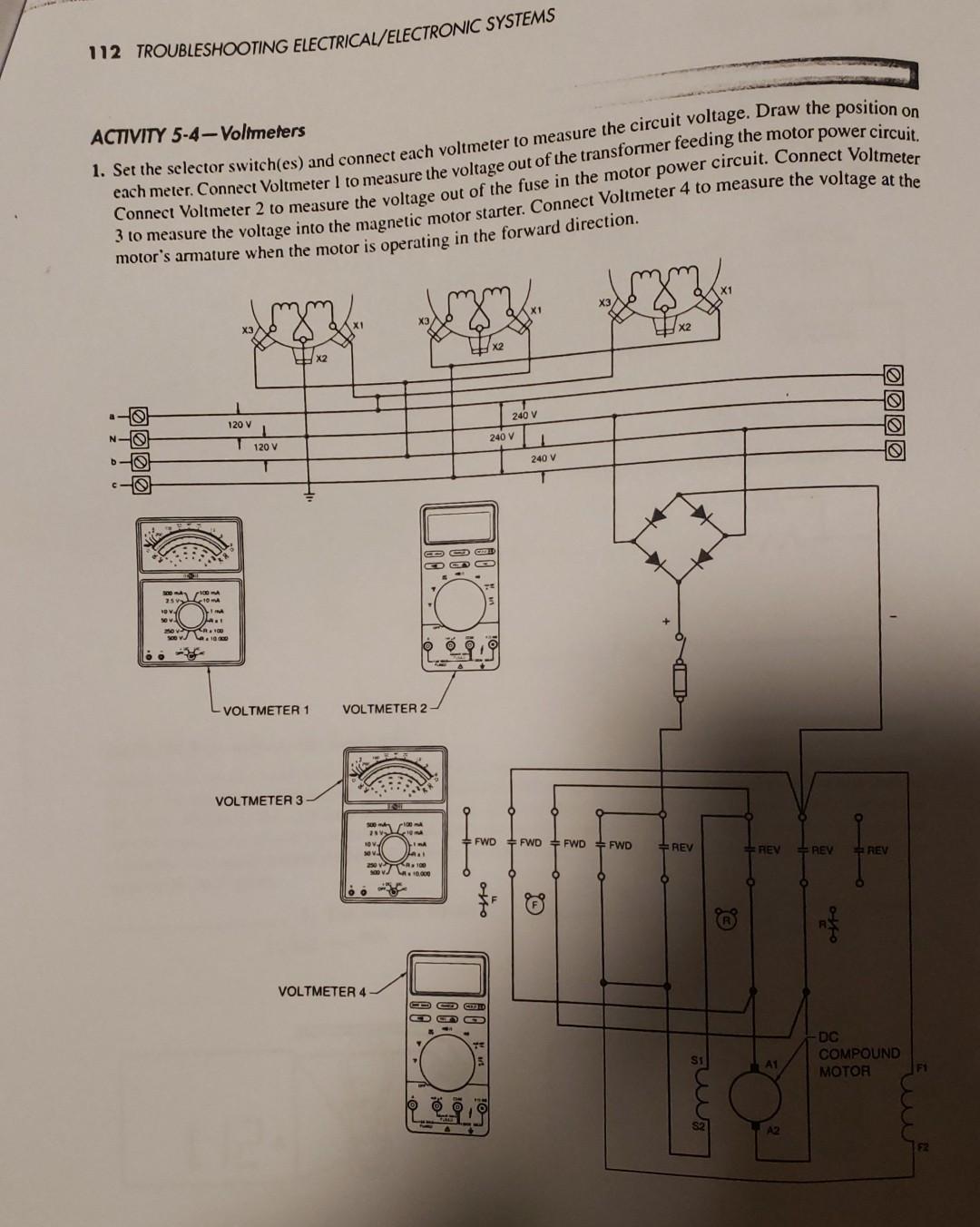

Begin by examining the system's schematic representations and specs. Comprehending the layout and functional specifications will offer context for diagnosing issues. Next off, separate the issue area by utilizing a procedure of elimination. This involves monitoring each part systematically, starting from the source of power and functioning towards the load.

Make use of screening equipment, such as multimeters and oscilloscopes, to collect objective data concerning voltage, present, and resistance at various factors within the system. This empirical evidence will certainly assist your troubleshooting initiatives and assist to verify or remove prospective sources of failure.

Additionally, take into consideration environmental variables that may affect the system's performance, such as temperature level changes or moisture ingress. A thorough assessment of wiring, connections, and parts will ensure that all possibilities are made up.

File Your Searchings For

Complete documentation is vital in the fixing procedure of electrical systems. This technique not only help in recognizing the origin cause of the problem but likewise offers as a reference her explanation for future troubleshooting efforts.

Furthermore, preserving a log of components replaced or repair services executed is very useful. This details sustains inventory administration and can help assess the long life and dependability of particular components.

Inevitably, the paperwork process must be complete yet concise, making it possible for simple retrieval and testimonial - electrical system troubleshooting. By prioritizing thorough documents, specialists can create a useful data base that not just aids in existing troubleshooting however additionally equips future upkeep efforts, therefore enhancing total system dependability

Prioritize Precaution

Recognizing the intrinsic risks connected with electric systems is essential for making certain safety throughout troubleshooting. Electric shock, burns, and equipment damages are simply a few of the prospective threats that specialists face. Prioritizing precaution is not only a legal responsibility yet also a moral critical that safeguards both the specialist and the surrounding environment.

Before starting any troubleshooting task, specialists ought to wear appropriate individual safety tools (PPE), consisting of insulated gloves, safety and security glasses, and flame-resistant clothes. Making sure that the workspace is completely dry and without clutter can substantially minimize the threat of crashes. In addition, it is essential to de-energize circuits before beginning any work, verifying that they are not live through using a multimeter or voltage tester.

Developing clear interaction procedures with group members is likewise important; this guarantees that everyone is aware of potential hazards and the status of the electrical system being worked with. Having an emergency reaction plan in place can confirm vital in the event of an event. By prioritizing safety and security procedures, service technicians can successfully mitigate threats and cultivate a more secure workplace.

Final Thought

Reliable electric system troubleshooting depends on a thorough understanding of essential concepts and a systematic method. Focusing on safety and security procedures makes certain the well-being of people entailed and visit this website the integrity of the electric system.

Report this page